Essential Information About Side Milling Cutters

By:Admin

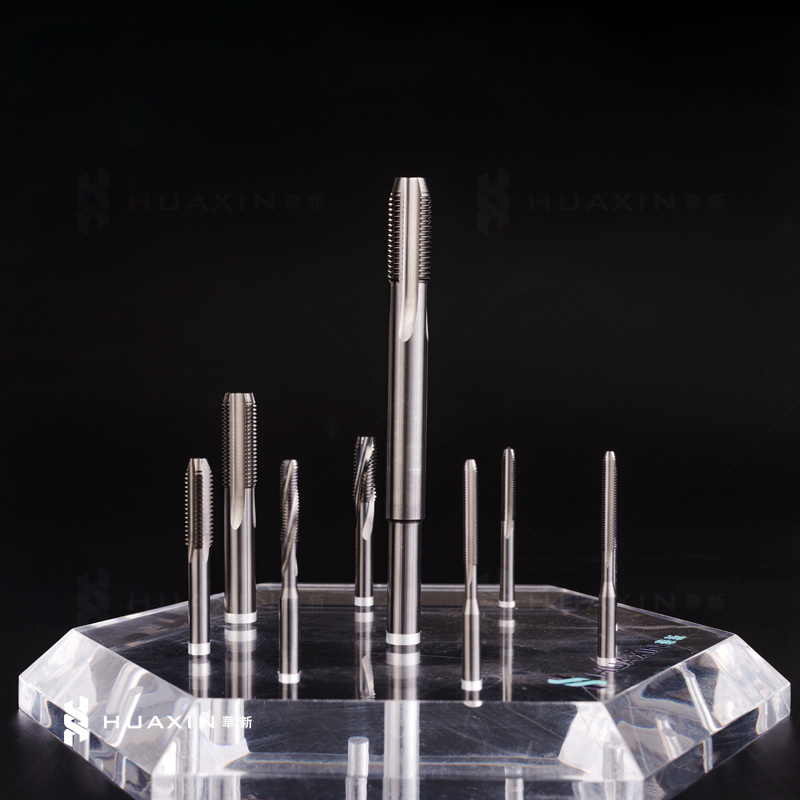

The Side Milling Cutter offers impeccable performance and versatility for a variety of materials including aluminum, stainless steel, and titanium. It is designed to deliver high-speed cutting and milling, effectively removing material from the workpiece with ease and accuracy. This innovative tool is engineered to provide superior surface finish and is suitable for both roughing and finishing operations, making it an essential addition to any machining arsenal.

"We are thrilled to introduce the Side Milling Cutter to the market," said the spokesperson for {Company Name}. "This cutting-edge tool is the result of extensive research and development, and we believe it will significantly enhance the productivity and efficiency of our customers' machining processes. We are committed to delivering cutting-edge solutions that meet the evolving needs of the industry, and the Side Milling Cutter is a testament to that commitment."

The Side Milling Cutter is manufactured using the highest quality materials and advanced production techniques, ensuring exceptional tool life and reliability. Its innovative design allows for optimal chip evacuation, minimizing heat buildup and prolonging tool longevity. The cutter is also engineered for easy maintenance and regrinding, further maximizing its cost-effectiveness and sustainability.

In addition to its exceptional performance, the Side Milling Cutter is designed with user convenience in mind. Its compatibility with a wide range of machining centers and milling machines makes it a versatile tool for various machining applications. The cutter is also available in a range of sizes and configurations to accommodate different cutting requirements, providing users with the flexibility to achieve their desired results.

{Company Name} is renowned for its commitment to innovation, quality, and customer satisfaction. With decades of experience in the cutting tool industry, the company has earned a reputation for delivering cutting-edge solutions that meet the diverse needs of its customers. The Side Milling Cutter is the latest addition to its extensive product lineup, embodying the company's dedication to pushing the boundaries of cutting technology.

The launch of the Side Milling Cutter is set to elevate {Company Name}'s position as a leading provider of cutting tools in the industry. The company's team of skilled engineers and technicians has worked tirelessly to develop this state-of-the-art tool, bringing together expertise, innovation, and a deep understanding of machining processes to create a product that sets new standards in cutting performance.

In conclusion, the Side Milling Cutter represents a significant advancement in cutting technology, offering unparalleled performance, durability, and versatility. With its exceptional cutting capabilities and user-friendly design, the cutter is poised to become an indispensable tool for machinists and manufacturers across various industries. {Company Name} is proud to introduce this groundbreaking innovation, and looks forward to empowering its customers with the tools they need to achieve excellence in machining.

Company News & Blog

Top Cutting Tool for Precision Machining: Long End Mill

Long End Mill, a leading manufacturer of cutting tools, has announced the launch of its latest end mill series, designed to meet the diverse needs of the machining industry. With a focus on precision engineering and high-performance materials, the new end mills are set to revolutionize the process of milling and cutting in various industrial applications.The company, known for its commitment to innovation and quality, has developed the new series of end mills to address the growing demand for advanced cutting tools that can deliver superior performance and extended tool life. By leveraging the latest technology and utilizing premium grade materials, Long End Mill aims to provide its customers with a competitive edge in their machining operations.The new end mill series features a range of cutting-edge designs, including high-performance flute geometries and specialized coatings that enhance wear resistance and tool longevity. These advanced features empower machinists to achieve higher material removal rates, improved surface finishes, and extended intervals between tool maintenance, leading to increased productivity and cost savings.With a comprehensive understanding of the challenges faced by machinists in various industries, Long End Mill has engineered the new series to offer versatility and performance across a wide range of materials, including steels, stainless steels, cast iron, and non-ferrous metals. This ensures that manufacturers and machine shops can rely on the end mills to deliver consistent results and exceptional machining capabilities across diverse applications.In addition to the innovative design and material advancements, Long End Mill has also focused on optimizing the manufacturing process to ensure strict adherence to quality and performance standards. The company's state-of-the-art production facilities leverage advanced CNC machinery and rigorous quality control measures to consistently deliver precision-engineered end mills that meet the demands of modern machining operations."We are excited to introduce our latest end mill series, which represents a significant leap forward in cutting tool technology," said the spokesperson for Long End Mill. "With a strong emphasis on performance, durability, and versatility, our new end mills are poised to empower machinists with the precision and reliability they need to excel in their machining tasks."The launch of the new end mill series underscores Long End Mill's commitment to pushing the boundaries of cutting tool innovation and setting new standards for performance and quality in the machining industry. By investing in research and development, as well as collaborating with industry experts and customers, the company aims to continuously enhance its product offerings and stay ahead of the evolving needs of the market.As the machining industry continues to evolve and demand higher levels of precision and efficiency, Long End Mill remains dedicated to providing cutting-edge solutions that enable manufacturers and machine shops to achieve their production goals with confidence. With the introduction of the new end mill series, the company reaffirms its position as a leader in the cutting tool sector and a trusted partner for businesses seeking to elevate their machining capabilities.With a strong track record of delivering innovative solutions and a commitment to excellence, Long End Mill is poised to make a lasting impact with its latest end mill series, offering machinists a competitive advantage and contributing to the advancement of the global machining industry.

Ultimate Guide to Slab Flattening Router Bits: Tips and Tricks

[Company Introduction: The company is a leading manufacturer of woodworking tools and equipment, with a strong reputation for producing high-quality products for professional woodworkers and hobbyists alike. With a focus on innovation and customer satisfaction, the company is committed to providing the best tools for a wide range of woodworking applications.]Slab Flattening Router Bit: The Solution for Flattening Large Wood SurfacesWoodworking enthusiasts and professionals know the challenges of working with large slabs of wood. Whether it's for a tabletop, countertop, or any other project, achieving a flat and smooth surface can be a daunting task. However, with the introduction of the Slab Flattening Router Bit from [Company Name], flattening large wood surfaces has become a much easier and more efficient process.The Slab Flattening Router Bit is specifically designed to remove excess material and level uneven surfaces, making it ideal for working with large, rough-cut slabs of wood. The bit features a large cutting diameter and multiple cutting flutes, allowing for quick and precise material removal. Its unique design also reduces the risk of chatter and ensures a smooth finish on even the toughest of woods.One of the key benefits of the Slab Flattening Router Bit is its versatility. It can be used with a wide range of router models and is compatible with both handheld and CNC machines. This flexibility makes it an essential tool for woodworkers of all levels, from hobbyists tackling their first big project to professionals working on custom furniture and other large-scale pieces.In addition to its practicality, the Slab Flattening Router Bit is built to last. Crafted from high-quality materials and engineered to withstand heavy use, this tool is designed for longevity and consistent performance. Woodworkers can rely on it to deliver exceptional results with each use, regardless of the project at hand.For those concerned about safety, the Slab Flattening Router Bit also comes with additional features to ensure a secure and stable cutting experience. Its shank is equipped with anti-kickback design, and the cutting edges are precision-ground for maximum sharpness and durability. These safety measures provide peace of mind, allowing woodworkers to focus on achieving the best possible finish for their projects.Given its effectiveness and reliability, the Slab Flattening Router Bit has garnered positive reviews from woodworking professionals and enthusiasts alike. Many have praised its ability to streamline the flattening process and produce consistent, high-quality results. Its ease of use and durability make it a valuable addition to any woodshop or toolkit.In conclusion, the Slab Flattening Router Bit from [Company Name] is a game-changer for woodworkers working with large slabs of wood. Its innovative design, versatility, and durability make it a must-have tool for anyone looking to achieve smooth, flat surfaces on their woodworking projects. Whether it's for a personal endeavor or a professional commission, this router bit delivers exceptional performance and results that speak for themselves.

Top Quality Boring Bars for Solid Performance

Solid Boring Bars: A Key Tool for Precision Machining in the Manufacturing IndustryIn the world of precision machining, solid boring bars are an essential tool for creating accurate and smooth bores in metal workpieces. These bars are designed to withstand the rigors of high-speed machining and are capable of producing holes with minimal vibration and excellent surface finish. J&K Corporation, a leading manufacturer of precision cutting tools and equipment, has been at the forefront of producing high-quality solid boring bars that meet the needs of the manufacturing industry.J&K Corporation is known for its dedication to creating innovative cutting tools that help machinists achieve the highest levels of precision and efficiency in their work. The solid boring bars produced by J&K are made from high-quality materials and undergo rigorous testing to ensure their durability and performance.One of the key features of J&K's solid boring bars is their advanced design, which includes specialized geometries and coatings that enhance cutting performance and tool life. This attention to detail allows machinists to achieve precise and consistent results, even when working with challenging materials such as hardened steel or heat-resistant alloys.The solid boring bars offered by J&K come in a variety of sizes and configurations to accommodate the diverse needs of the manufacturing industry. Whether a machinist is working on a small-scale project or a large-scale production run, they can find a solid boring bar from J&K that meets their specific requirements.In addition to their high-performance capabilities, J&K's solid boring bars are also designed with user-friendly features that make them easy to set up and operate. This includes secure clamping mechanisms and chip evacuation systems that help to prevent tool damage and ensure a smooth machining process.Furthermore, J&K Corporation stands out in the industry for its commitment to providing excellent customer support and technical assistance. The company's team of experts is available to provide guidance on selecting the right solid boring bar for a particular application, as well as offer advice on optimizing machining processes for maximum efficiency and quality.The use of solid boring bars in precision machining offers several advantages for manufacturers. Not only do these tools help to achieve tight tolerances and fine surface finishes, but they also contribute to reducing cycle times and overall production costs. With the right solid boring bar from J&K, manufacturers can streamline their machining operations and improve the quality of their end products.J&K Corporation's solid boring bars have been widely adopted by leading manufacturers in various industries, including aerospace, automotive, medical, and mold making. The company's commitment to producing reliable and high-performance cutting tools has earned it a strong reputation and a loyal customer base.As the manufacturing industry continues to demand higher levels of precision and productivity, the need for reliable and efficient cutting tools like solid boring bars will only grow. J&K Corporation is poised to meet this demand with its ongoing commitment to innovation and quality in the production of solid boring bars and other cutting tools.In conclusion, solid boring bars are a crucial tool for achieving precision machining in the manufacturing industry. J&K Corporation's dedication to producing high-quality solid boring bars that meet the needs of machinists and manufacturers has established the company as a trusted leader in the cutting tool industry. With their advanced design, durability, and user-friendly features, J&K's solid boring bars offer unmatched performance and reliability for a wide range of machining applications. As the manufacturing industry continues to evolve, J&K Corporation remains at the forefront of providing cutting-edge solutions for precision machining.

The Benefits of CNC Milling and its Impact on Manufacturing

In today's rapidly evolving manufacturing industry, precision is key. Companies are constantly seeking out cutting-edge technologies to improve their production processes and deliver high-quality products to their clients. One such technology that has revolutionized the manufacturing sector is CNC milling, a highly efficient and accurate method of machining. With the help of CNC milling, companies are able to produce complex components with unparalleled precision and speed, making it an indispensable tool in the modern manufacturing world.CNC milling, also known as computer numerical control milling, is a manufacturing process that utilizes computerized controls and rotating multi-point cutting tools to progressively remove material from a workpiece. This process is highly versatile and can be used to create a wide range of components, from simple to highly intricate parts. The ability to program the exact specifications into the CNC machine allows for precise and repetitive production, ensuring consistent quality in every piece produced.One company at the forefront of CNC milling technology is [Company Name]. Founded in [Year], [Company Name] has established itself as a leading provider of precision machining services. Their state-of-the-art facility is equipped with the latest CNC milling machines, allowing them to meet the most demanding requirements of their clients in a variety of industries, including aerospace, automotive, medical, and more.With a team of highly skilled engineers, machinists, and quality control experts, [Company Name] is dedicated to delivering superior products that meet and exceed their customers' expectations. Their commitment to continuous improvement and investment in cutting-edge technologies has positioned them as a trusted partner for businesses looking for high-quality precision components.One of the key advantages of CNC milling is its ability to produce components with extremely tight tolerances, making it ideal for industries where precision is paramount. The process is capable of creating complex geometries and intricate designs with unmatched accuracy, allowing [Company Name] to take on projects that may be challenging for traditional machining methods.This level of precision also translates to improved efficiency, as CNC milling can produce parts at a faster rate than conventional methods. The automation and programmability of CNC machines greatly reduce the risk of human error and enable continuous production runs with minimal downtime, resulting in cost savings for both [Company Name] and their clients.Furthermore, CNC milling allows for a high degree of customization, enabling [Company Name] to tailor their manufacturing processes to the specific needs of each project. This flexibility is especially valuable in industries where unique or one-of-a-kind components are required, as it allows for rapid prototyping and fast iterations to meet customer specifications.In addition to their advanced CNC milling capabilities, [Company Name] also offers a range of secondary processes to further enhance the quality and functionality of their components. From precision grinding and heat treatment to surface finishing and assembly, they provide a comprehensive suite of services to ensure that their products meet the highest standards of excellence.As the manufacturing industry continues to evolve, the demand for precision components will only increase. Companies like [Company Name] are poised to meet this demand with their expertise in CNC milling and their unwavering commitment to delivering top-notch products. With a combination of cutting-edge technology, skilled professionals, and a customer-centric focus, [Company Name] is well-positioned to remain a leader in the field of precision machining.In conclusion, CNC milling has become an indispensable tool in the modern manufacturing industry, enabling companies like [Company Name] to produce complex components with unparalleled precision, efficiency, and customization. As technology continues to advance, we can expect to see even greater innovations in CNC milling, further solidifying its place as a cornerstone of the manufacturing world.

Durable Cemented Carbide Material Taps for Industrial Use

Cemented Carbide Material Taps: The Next Generation of Industrial SolutionsIn recent years, the industrial sector has seen a significant shift towards advanced and innovative materials that can withstand the demands of high-performance applications. Among these materials, cemented carbide has emerged as a superior option for various industrial tools and components, including cutting tools, drills, and taps. With its exceptional hardness, strength, and wear resistance, cemented carbide is revolutionizing the way industries operate, providing advanced solutions that are essential for enhancing productivity, efficiency, and overall performance.The latest breakthrough in this field comes from the renowned company [Company Name], a leading producer of cemented carbide material taps. With a strong commitment to cutting-edge research and development, [Company Name] has introduced a new generation of cemented carbide material taps that are set to redefine the industrial landscape. Leveraging their extensive expertise and state-of-the-art manufacturing facilities, [Company Name] has developed a range of taps that offer unparalleled durability, precision, and reliability, meeting the diverse needs of industries such as aerospace, automotive, oil and gas, and medical manufacturing.The secret behind the exceptional performance of [Company Name]'s cemented carbide material taps lies in the unique properties of the material itself. Cemented carbide, also known as hard metal, is composed of a combination of tungsten carbide and cobalt, resulting in a material that is exceptionally hard and wear-resistant. This hardness enables the taps to withstand extreme temperatures and pressures, making them ideal for use in challenging machining environments. Furthermore, the superior wear resistance of cemented carbide ensures that the taps maintain their cutting edge sharpness for extended periods, reducing downtime and tool replacement costs for industrial users.Aside from its remarkable physical properties, cemented carbide also offers excellent dimensional stability and corrosion resistance, making it an ideal choice for precision machining applications. These qualities are particularly important in industries that demand high accuracy and repeatability, such as aerospace and medical manufacturing, where the smallest deviations can result in costly errors. With [Company Name]'s cemented carbide material taps, industrial users can achieve the level of precision and consistency required for their critical operations, ensuring the quality and reliability of their products.What sets [Company Name]'s cemented carbide material taps apart from the competition is their advanced design and engineering. The company's team of experts has leveraged their in-depth knowledge of material science and cutting tool technology to develop taps that are optimized for maximum performance. This includes the careful selection of carbide grades, coatings, and geometries, as well as the use of advanced manufacturing processes to ensure the highest quality and consistency in every tap produced. As a result, [Company Name]'s taps deliver superior chip control, improved tool life, and enhanced productivity, providing a competitive edge for industrial users across various sectors.In addition to their technical excellence, [Company Name]'s cemented carbide material taps also reflect the company's commitment to sustainability and environmental responsibility. By promoting the use of durable and long-lasting tools, [Company Name] contributes to reducing the consumption of resources and the generation of waste associated with tool replacement and disposal. Furthermore, their taps are designed to optimize machining processes, resulting in energy savings and reduced carbon emissions for their users. This aligns with [Company Name]'s broader mission to develop innovative solutions that not only benefit their customers but also contribute to a more sustainable and efficient industrial ecosystem.Looking ahead, [Company Name] is poised to continue leading the way in the development of cemented carbide material taps, with ongoing investment in research and development, as well as collaboration with industry partners to address the evolving needs of the market. By harnessing the potential of cemented carbide and leveraging their expertise, [Company Name] is set to drive further innovations in industrial tools and components, setting new standards for performance, reliability, and sustainability.In conclusion, [Company Name]'s cemented carbide material taps represent a significant advancement in industrial solutions, offering a combination of exceptional properties, advanced design, and environmental responsibility. As industries continue to seek high-performance tools capable of meeting their demanding requirements, the emergence of cemented carbide material taps signals a new era in the evolution of industrial materials. With [Company Name] at the forefront of this movement, the future looks promising for those seeking cutting-edge solutions to drive their productivity and success.

High-Quality End Mill Cutter: The Ultimate Guide for Machinists

Cutter end mills are an essential tool in the manufacturing industry, especially in the production of precision parts and components. These specialized cutting tools are designed to remove material from a workpiece to create a specific shape, and they are widely used in industries such as aerospace, automotive, and medical device manufacturing.One company that has gained a reputation for producing high-quality cutter end mills is [Company Name]. With a history of over 20 years in the industry, [Company Name] has established itself as a leading manufacturer of cutting tools, serving customers worldwide.The company prides itself on its state-of-the-art manufacturing facilities and a team of experienced engineers and technicians who are dedicated to producing precision-engineered end mills that meet the most demanding industry standards. With a focus on innovation and continuous improvement, [Company Name] is constantly developing new cutting tool designs and advanced manufacturing processes to stay ahead of the competition.In addition to its commitment to quality and innovation, [Company Name] places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific cutting tool needs and provides customized solutions to meet their requirements. This customer-centric approach has earned [Company Name] a loyal customer base and a reputation for delivering reliable and high-performance end mills.Recently, [Company Name] introduced a new line of cutter end mills that has generated a great deal of excitement in the industry. These cutting tools feature a unique design that allows for higher material removal rates, reduced cutting forces, and extended tool life. The new end mills also incorporate advanced coatings and geometries that result in improved surface finishes and dimensional accuracy.According to [Company Name]'s CEO, the development of these new cutter end mills is a result of extensive research and development efforts aimed at addressing the evolving needs of the manufacturing industry. The company is committed to providing its customers with cutting-edge solutions that improve their operational efficiency and productivity.The new line of cutter end mills has already garnered positive feedback from customers who have tested the tools in real-world manufacturing applications. Many have reported significant improvements in their machining processes, including reduced cycle times, lower production costs, and improved overall product quality.In addition to its focus on product development, [Company Name] is also dedicated to supporting its customers with technical expertise and after-sales service. The company's team of engineers and application specialists are readily available to provide assistance with tool selection, machining strategies, and troubleshooting, ensuring that customers get the most out of their cutting tools.Looking ahead, [Company Name] aims to continue its commitment to innovation and excellence in the field of cutting tools. The company plans to expand its product line and further enhance its manufacturing capabilities to meet the growing demands of the global manufacturing industry.In conclusion, [Company Name] is a leading manufacturer of cutter end mills, known for its dedication to quality, innovation, and customer satisfaction. With its recent introduction of a new line of advanced cutting tools, the company is set to further solidify its position as a trusted partner for manufacturers seeking high-performance end mills. As the manufacturing industry continues to evolve, [Company Name] remains at the forefront, providing cutting-edge solutions that drive operational efficiency and productivity for its customers.

Top Quality Diamond Cutting Disc for Precision Cutting Tasks

[Company Name] Introduces High-Quality Diamond Cutting Discs for Precision Cutting Needs[City, State] - The demand for precision cutting tools has been steadily increasing in various industries, and [Company Name] is stepping up to meet this demand with the introduction of its high-quality diamond cutting discs. With a commitment to providing innovative and reliable cutting solutions, [Company Name] aims to revolutionize the cutting tool industry with its latest product offering.The diamond cutting discs offered by [Company Name] are designed to deliver exceptional precision and durability for a wide range of cutting applications. Whether it's for cutting through concrete, stone, ceramic, or other hard materials, [Company Name]'s diamond cutting discs are engineered to provide a superior cutting performance that meets the highest standards."We are proud to announce the launch of our diamond cutting discs, which have been meticulously developed to meet the evolving needs of our customers," said [Spokesperson Name], the [Title] at [Company Name]. "We understand the importance of having reliable cutting tools that deliver precision and efficiency, which is why we have invested in the latest technology and materials to create a product that exceeds expectations."The diamond cutting discs offered by [Company Name] are constructed with high-quality diamond particles that are bonded to a durable metal core. This construction allows for smooth and precise cutting, while also ensuring long-lasting performance even in the most demanding cutting conditions. Additionally, the discs are designed to reduce vibration and noise during operation, providing a more comfortable and efficient cutting experience for users.In addition to their exceptional cutting performance, [Company Name]'s diamond cutting discs are also engineered to maximize safety and convenience for the user. The discs feature a reinforced design for added strength and stability, as well as easy-to-read markings for quick and accurate size identification. Furthermore, the discs are designed for compatibility with a wide range of cutting tools, making them a versatile and practical choice for various cutting needs.As a leading provider of cutting tools and solutions, [Company Name] is dedicated to delivering products that not only meet but exceed industry standards. The introduction of its diamond cutting discs is a testament to this commitment, as the company continues to innovate and push the boundaries of what is possible in the cutting tool industry."We are confident that our diamond cutting discs will set a new standard for precision cutting tools," added [Spokesperson Name]. "With our relentless focus on quality, performance, and innovation, we believe that these discs will become the go-to choice for professionals in a wide range of industries."With the launch of its diamond cutting discs, [Company Name] is poised to make a significant impact in the cutting tool market. As the company continues to expand its product offerings and push the boundaries of cutting technology, customers can expect even more innovative and high-quality solutions from [Company Name] in the future.For more information about [Company Name]'s diamond cutting discs and other cutting tool solutions, please visit [Company Website] or contact [Company Name] directly at [Contact Information].About [Company Name]:[Company Name] is a leading provider of cutting tools and solutions for a wide range of industries. With a focus on innovation, quality, and reliability, [Company Name] is committed to delivering cutting-edge products that meet the evolving needs of its customers. From diamond cutting discs to saw blades and beyond, [Company Name] continues to set the standard for quality and performance in the cutting tool industry.Contact Information:[Company Name][Address][City, State, Zip Code][Phone Number][Email Address][Company Website]

Top 10 Essential Welding Tools for Your DIY Projects

Welding Tools Unveils New Line of Innovative ProductsWelding Tools, a leading manufacturer of welding and cutting equipment, has recently announced the launch of a new line of innovative products designed to meet the evolving needs of the welding industry. The company, which has been a prominent player in the welding equipment market for over 50 years, has earned a reputation for its high-quality, reliable products.The new line of products includes a range of welding machines, cutting torches, and welding accessories, all of which have been designed with the latest technological advancements in mind. These products have been engineered to deliver superior performance, increased productivity, and enhanced safety for welders and fabricators across various industries."We are thrilled to introduce our new line of welding products, which represent the culmination of extensive research, development, and innovation," said a spokesperson for Welding Tools. "Our goal is to provide our customers with the tools they need to achieve exceptional results and stay ahead in an increasingly competitive industry."The new line of products features several standout offerings, including state-of-the-art welding machines that offer advanced features such as digital displays, multi-process capabilities, and enhanced arc control. These machines are designed to provide precise and consistent welds across a variety of applications, while also being highly durable and easy to maintain.In addition to welding machines, Welding Tools has also introduced a new range of cutting torches that are engineered for maximum precision and efficiency. These torches incorporate innovative designs and materials to deliver superior performance, making them ideal for tasks such as metal fabrication, construction, and automotive repair.Complementing the welding machines and cutting torches, the company has also expanded its line of welding accessories to include new and improved welding helmets, gloves, and protective clothing. These accessories are designed to enhance the safety and comfort of welders, while also providing them with the necessary tools to carry out their work with precision and confidence.Welding Tools' commitment to innovation and excellence is evident in the design and performance of its new products. Each item in the new line has undergone rigorous testing and quality control to ensure that it meets the highest industry standards. The company's investment in research and development has enabled it to stay at the forefront of welding technology, continually pushing the boundaries of what is possible in this field."We are proud of the advancements we have made with our new line of welding products, and we are confident that they will make a significant impact in the industry," said the spokesperson. "We have listened to the needs of our customers and have responded with products that are not only reliable and efficient but also easy to use and maintain."As Welding Tools continues to gain recognition for its new line of innovative products, the company remains committed to providing exceptional customer service and support. Its team of knowledgeable and dedicated professionals is readily available to assist customers with product selection, technical support, and troubleshooting, ensuring that they have a positive experience with Welding Tools from start to finish.With its unwavering dedication to quality, innovation, and customer satisfaction, Welding Tools is poised to maintain its position as a leader in the welding equipment market for many years to come. The launch of its new line of products is a testament to the company's ongoing commitment to meeting the diverse and evolving needs of welders and fabricators worldwide.

New Electric Drill Innovation Makes Boring Bits a Thing of the Past

Boring Bit Drill, a leading provider of innovative drilling solutions, has recently announced the launch of their newest product, the X-Drill. The X-Drill is a revolutionary drilling tool that promises to significantly improve drilling efficiency and accuracy in various industrial applications.The X-Drill is designed to meet the growing demand for advanced drilling solutions that can effectively handle the challenges of modern drilling operations. With its advanced technology and cutting-edge design, the X-Drill offers a range of features and benefits that set it apart from traditional drilling tools.One of the key features of the X-Drill is its high-speed drilling capability, which allows for faster and more efficient drilling in a wide range of materials, including metal, wood, and composite materials. This means that the X-Drill can help companies save time and reduce costs by increasing productivity and minimizing downtime.In addition to its high-speed drilling capability, the X-Drill also offers superior accuracy and precision, thanks to its advanced guidance system and state-of-the-art sensors. This ensures that each drilling operation is carried out with the highest level of precision, leading to improved quality and consistency in the final product.Furthermore, the X-Drill is equipped with advanced safety features to protect both the operator and the equipment. This includes a built-in safety mechanism that automatically stops the drill in case of a malfunction or an unexpected obstacle, reducing the risk of accidents and injuries in the workplace.The X-Drill is also designed with versatility in mind, with the ability to accommodate a wide range of drill bit sizes and types. This means that it can be used for a variety of drilling tasks, from simple holes to more complex drilling operations, making it a valuable tool for a wide range of industries."We are thrilled to introduce the X-Drill to the market," said the spokesperson of Boring Bit Drill. "We believe that this innovative new product will revolutionize the way drilling operations are carried out, and will help our customers improve their productivity, efficiency, and safety in the workplace."Boring Bit Drill has built a solid reputation in the industry for delivering high-quality drilling solutions that meet the evolving needs of their customers. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of drilling technology to provide cutting-edge solutions that help their customers stay ahead of the competition.The launch of the X-Drill is a testament to Boring Bit Drill's dedication to innovation and quality, and their continued pursuit of excellence in drilling technology. The company is confident that the X-Drill will make a significant impact in the industry and help their customers achieve new levels of productivity and success.As the demand for advanced drilling solutions continues to grow, Boring Bit Drill remains at the forefront of the industry, leading the way with their innovative products and commitment to customer satisfaction. With the launch of the X-Drill, the company is poised to further solidify their position as a trusted provider of cutting-edge drilling solutions in the global market.In conclusion, the launch of the X-Drill by Boring Bit Drill represents a major milestone in the drilling industry, offering a powerful and versatile solution that is set to transform the way drilling operations are carried out. With its advanced features and benefits, the X-Drill is poised to make a significant impact in the industry and help companies improve their productivity, efficiency, and safety. Boring Bit Drill continues to lead the way in drilling technology, and the launch of the X-Drill further reinforces their commitment to innovation and excellence.

High-quality Carbide Thread Mill for Precision Machining

Carbide Thread Mill Revolutionizes Industrial MetalworkingThe latest innovation in the world of metalworking has arrived with the introduction of a cutting-edge Carbide Thread Mill by a renowned manufacturing company. This revolutionary tool is set to transform the way in which industrial professionals approach the machining and threading of metals, offering a level of precision and efficiency that has never before been possible.For decades, the process of machining and threading metal has been a time-consuming and labor-intensive task. Traditional methods often involve the use of multiple tools and techniques, leading to extended production times and inconsistent results. The Carbide Thread Mill, however, has been specifically designed to streamline this process, providing a comprehensive solution that delivers precise and high-quality threading in a fraction of the time.One of the key features that sets the Carbide Thread Mill apart from its predecessors is its use of advanced carbide materials. These cutting-edge materials have been carefully selected for their exceptional hardness and durability, ensuring that the tool maintains its sharpness and effectiveness over an extended period of use. This means that industrial professionals can rely on the Carbide Thread Mill to consistently deliver superior results, without the need for frequent replacement or maintenance.Furthermore, the unique design of the Carbide Thread Mill allows for enhanced chip evacuation, minimizing the risk of clogging and reducing the likelihood of tool breakage. This not only contributes to a safer working environment, but also maximizes the tool's productivity and longevity. As a result, industrial professionals can complete threading tasks with confidence and efficiency, knowing that the Carbide Thread Mill is equipped to handle even the most challenging materials and applications.In addition to its exceptional performance, the Carbide Thread Mill is also highly versatile, offering compatibility with a wide range of metal types and thread sizes. This adaptability makes it a valuable addition to any industrial metalworking operation, enabling professionals to tackle an extensive variety of projects with ease and precision. Whether working with aluminum, steel, or titanium, the Carbide Thread Mill's ability to deliver consistently accurate results remains unmatched.The release of the Carbide Thread Mill marks a significant advancement in the field of metalworking, presenting a game-changing tool that has the potential to revolutionize the way in which threads are machined. Its combination of cutting-edge materials, innovative design, and unparalleled precision sets a new standard for efficiency and quality in industrial metalworking, establishing it as an essential tool for any professional seeking to optimize their threading processes. With the Carbide Thread Mill, industrial professionals can expect to achieve superior results in less time, ultimately leading to increased productivity and profitability for their operations.With an unwavering commitment to excellence and innovation, the manufacturing company behind the Carbide Thread Mill continues to lead the way in developing groundbreaking solutions for the metalworking industry. Their dedication to research and development has resulted in the creation of a tool that not only exceeds current industry standards, but also anticipates the evolving needs of industrial professionals in an ever-changing market. As a result, the company has earned a reputation as a trusted and reliable partner for those seeking to optimize their metalworking processes and achieve unparalleled results.In conclusion, the introduction of the Carbide Thread Mill represents a significant milestone in the advancement of industrial metalworking. Its exceptional performance, versatility, and durability position it as an indispensable tool for any professional seeking to elevate their threading processes to new heights of precision and efficiency. With the Carbide Thread Mill, the future of metalworking has arrived, offering a level of quality and reliability that is truly unmatched in the industry.