High-Quality Cutting Disc for Precision Metal Cutting - A Complete Guide

By:Admin

In today’s fast-paced world, industries are constantly looking for innovative solutions to improve efficiency and productivity. One such innovation that has revolutionized the cutting industry is the cutting disc. This cutting-edge technology has transformed the way materials are cut, making the process faster, more precise, and cost-effective.

{Company Name} is at the forefront of this revolution, providing high-quality cutting discs that are setting new standards in the industry. As a leading manufacturer in the cutting tool industry, {Company Name} has been delivering cutting-edge solutions to a wide range of industries including construction, metal fabrication, automotive, and aerospace.

The cutting disc offered by {Company Name} is designed to deliver exceptional performance and longevity. Made from premium quality materials, these cutting discs are engineered to withstand the toughest cutting applications. The advanced design and manufacturing process ensure that the discs offer superior cutting performance, reduced downtime, and increased productivity.

One of the key advantages of {Company Name}'s cutting discs is their ability to cut through various materials with precision and ease. Whether it is steel, stainless steel, aluminum, or other ferrous and non-ferrous metals, these cutting discs deliver clean and accurate cuts, making them an ideal choice for a wide range of cutting applications.

Moreover, {Company Name}'s cutting discs are designed to operate at high speeds, allowing for faster cutting without compromising on precision. This not only saves time but also improves overall efficiency in the cutting process. Additionally, the discs are engineered to produce minimal heat and vibration, resulting in a smooth cutting experience and extending the life of the cutting disc.

Another notable feature of {Company Name}'s cutting discs is their versatility. These discs are suitable for use with a variety of cutting tools including angle grinders, chop saws, and circular saws. This flexibility makes them a versatile option for different cutting requirements, further adding to their appeal in the industry.

In addition to the exceptional performance, {Company Name} also prides itself on its commitment to safety and environmental sustainability. The cutting discs are designed to meet stringent safety standards, ensuring a safe working environment for operators. Furthermore, {Company Name} continuously strives to minimize the environmental impact of its products through responsible manufacturing practices and eco-friendly materials.

Furthermore, {Company Name} provides comprehensive support and expertise to its customers. With a team of experienced professionals, the company offers technical assistance, guidance on selecting the right cutting disc, and after-sales support, ensuring that customers get the most out of their cutting disc investment.

As a testament to their quality and performance, {Company Name}'s cutting discs have gained recognition and trust from customers worldwide. The company's commitment to excellence and continuous innovation has made it a preferred choice for businesses looking to enhance their cutting operations.

In conclusion, the cutting disc has undoubtedly transformed the cutting industry, and {Company Name} is leading the way with its high-performance and versatile cutting discs. With a focus on quality, precision, and innovation, the company is setting new benchmarks in the cutting tool industry. As industries continue to evolve, {Company Name} remains committed to delivering cutting-edge solutions that empower businesses to achieve new heights of efficiency and productivity.

For more information about {Company Name} and its cutting discs, visit their website or contact their customer support team.

Company News & Blog

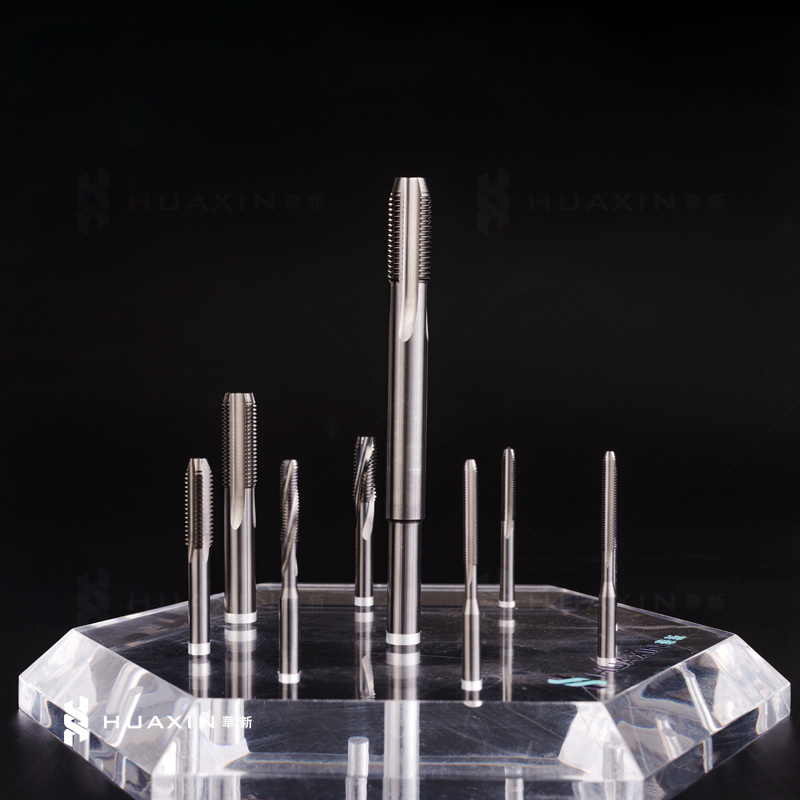

Learn About the Benefits of Carbide Forming Taps for Your Metalworking Needs

Carbide Forming Taps, also known as CNC taps, are high-performance cutting tools widely used in the machining industry for their efficiency and accuracy. These taps are designed to create internal threads in various materials such as steel, aluminum, and other alloys with precision and repeatability. With the increasing demand for high-quality threading in the manufacturing sector, carbide forming taps have become a critical tool for achieving superior thread quality and production efficiency.{Company} is a leading manufacturer of carbide forming taps, specializing in the design and production of high-quality cutting tools for the metalworking industry. With a strong focus on innovation and advanced machining technology, {Company} has established a reputation for delivering reliable and high-performance tools to meet the evolving needs of modern manufacturing.The carbide forming taps manufactured by {Company} are engineered to deliver superior threading performance in a wide range of materials, including stainless steel, cast iron, and titanium. These taps are designed with precision-ground carbide inserts to ensure consistent and accurate thread forming, minimizing the risk of tool wear and thread defects. The advanced coating technology used in these taps further enhances their durability and tool life, making them an ideal choice for high-volume production environments.One of the key advantages of {Company}'s carbide forming taps is their ability to improve productivity and reduce machining costs. The high cutting speeds and feed rates achieved with these taps result in shorter cycle times and increased throughput, allowing manufacturers to boost their overall production efficiency. Additionally, the exceptional thread quality and surface finish produced by these taps contribute to improved product integrity and customer satisfaction.In addition to their performance benefits, {Company}'s carbide forming taps are also designed for easy setup and operation, making them suitable for both CNC machining centers and conventional tapping applications. This versatility allows manufacturers to leverage the advantages of carbide forming taps across a wide range of production processes, further enhancing their operational flexibility and resource utilization.Furthermore, {Company} provides comprehensive technical support and expertise to assist customers in selecting the right carbide forming taps for their specific applications. The company's team of engineering and machining experts works closely with customers to understand their machining challenges and develop tailored solutions that optimize tool performance and overall productivity. This customer-centric approach has established {Company} as a trusted partner for manufacturers seeking to enhance their machining capabilities and achieve superior threading results.As the manufacturing industry continues to embrace advanced machining technologies and processes, the demand for high-performance cutting tools such as carbide forming taps is expected to grow. {Company} is committed to staying at the forefront of this trend by investing in research and development to further enhance the performance and capabilities of its carbide forming taps. This ongoing commitment to innovation and quality ensures that {Company} remains a preferred supplier of cutting-edge threading solutions for manufacturers worldwide.In conclusion, carbide forming taps are essential tools for achieving superior thread quality and production efficiency in the machining industry. {Company} has demonstrated its leadership in this space by delivering high-performance carbide forming taps that enable manufacturers to optimize their machining processes, enhance productivity, and achieve exceptional threading results. With a focus on innovation, quality, and customer support, {Company} continues to be a trusted partner for manufacturers seeking reliable and high-performance cutting tools for their production needs.

High-Quality Corner Rounding End Mill for Precision Machining

Corner Rounding End Mill: A Tool for Precision MachiningIn the world of manufacturing and machining, precision and accuracy are non-negotiable. The tools used in these processes must be of the highest quality to ensure that the end products meet the strictest standards. One such tool that is essential in precision machining is the Corner Rounding End Mill.The Corner Rounding End Mill, offered by {Company Name}, is a cutting tool used in a variety of machining applications. It is designed to remove material from a workpiece's interior and exterior edges, creating a rounded edge. This is essential in many manufacturing processes, as rounded edges offer several benefits, such as improved durability, reduced stress concentration, and enhanced aesthetic appeal.{Company Name} is a leading manufacturer of cutting tools and precision machining solutions. With a strong commitment to innovation and quality, the company has earned a reputation for providing high-performance tools that meet the needs of the most demanding machining applications. The Corner Rounding End Mill is just one example of the company's dedication to providing cutting-edge solutions for the manufacturing industry.The Corner Rounding End Mill is available in a variety of sizes and configurations to accommodate different machining requirements. It is made from high-quality materials and features advanced cutting geometries that ensure optimal performance and longevity. Additionally, {Company Name} offers custom tooling solutions, allowing customers to tailor the Corner Rounding End Mill to their specific machining needs.One of the key features of the Corner Rounding End Mill is its ability to achieve precise and consistent results. This is crucial in manufacturing, where even the smallest deviation from the intended specifications can lead to costly rework and production delays. The high-precision design of the tool, combined with {Company Name}'s stringent quality control processes, ensures that each Corner Rounding End Mill delivers reliable and repeatable performance.Another advantage of the Corner Rounding End Mill is its versatility. It can be used in various materials, including metals, plastics, and composites, making it a valuable tool for a wide range of industries, such as aerospace, automotive, medical, and general machining. Whether it's deburring, edge breaking, or creating a smooth transition between different surfaces, the Corner Rounding End Mill excels in delivering the desired results.In addition to its performance capabilities, {Company Name} also provides comprehensive technical support and expertise to help customers maximize the potential of the Corner Rounding End Mill. The company's team of engineers and application specialists are readily available to offer guidance on tool selection, machining parameters, and process optimization, ensuring that customers can make the most of their investment in {Company Name}'s cutting tools.As the manufacturing industry continues to evolve, the demand for high-quality cutting tools like the Corner Rounding End Mill will only continue to grow. With its focus on innovation, quality, and customer satisfaction, {Company Name} is well-positioned to meet these demands and continue providing cutting-edge solutions for precision machining.In conclusion, the Corner Rounding End Mill offered by {Company Name} stands as a testament to the company's commitment to excellence in cutting tools and precision machining solutions. With its high-performance design, versatility, and comprehensive support, the Corner Rounding End Mill is a valuable asset for manufacturers seeking to achieve superior results in their machining operations. As the manufacturing industry pushes boundaries and demands greater precision, {Company Name} remains at the forefront, delivering innovative solutions that empower its customers to stay ahead of the competition.

Top 10 Essential Cutting Tools and Equipment for DIY Projects

Cutting Tools And Equipment Company is a leading supplier of high-quality cutting tools and equipment for a wide range of industries. With a focus on providing innovative and reliable solutions for cutting and shaping materials, the company has established a reputation for excellence and customer satisfaction. With a comprehensive product line and a commitment to continuous improvement, Cutting Tools And Equipment Company is poised to meet the needs of its clients and exceed their expectations.The company offers a wide selection of cutting tools and equipment, including saw blades, drill bits, milling cutters, and more. These products are designed to deliver superior performance and durability, allowing customers to achieve precise and efficient cutting results. Whether it's for metalworking, woodworking, or other applications, Cutting Tools And Equipment Company has the right tools for the job.One of the key strengths of Cutting Tools And Equipment Company is its ability to provide customized solutions for specific customer requirements. The company's team of experts works closely with clients to understand their needs and develop tailored cutting tool solutions that meet their unique specifications. This personalized approach sets Cutting Tools And Equipment Company apart from its competitors and has earned the trust and loyalty of numerous customers.In addition to its focus on product excellence, Cutting Tools And Equipment Company also places a strong emphasis on customer service. The company's knowledgeable and experienced staff are dedicated to providing timely and effective support to clients, ensuring that they have the information and assistance they need to make informed decisions. This commitment to customer satisfaction has made Cutting Tools And Equipment Company a preferred partner for businesses seeking reliable cutting tool solutions.Furthermore, Cutting Tools And Equipment Company is committed to staying at the forefront of technological advancements in the cutting tools industry. The company invests in research and development to continuously improve its products and explore new capabilities. By staying ahead of the curve, Cutting Tools And Equipment Company ensures that its customers have access to the latest cutting tools and equipment, allowing them to stay competitive in their respective markets.As part of its commitment to quality and innovation, Cutting Tools And Equipment Company has also implemented stringent quality control measures throughout its manufacturing processes. The company adheres to rigorous standards to ensure that its products are produced to the highest quality and performance standards. This dedication to quality and consistency has earned Cutting Tools And Equipment Company numerous certifications and accolades, further reinforcing its position as a trusted provider of cutting tools and equipment.Looking ahead, Cutting Tools And Equipment Company is focused on expanding its market presence and reaching new customers across various industries. The company is actively seeking partnerships and collaborations to broaden its reach and deliver its cutting tools and equipment to a wider audience. By leveraging its expertise and resources, Cutting Tools And Equipment Company aims to become a leading force in the cutting tools industry, offering unparalleled solutions and support to its growing customer base.In conclusion, Cutting Tools And Equipment Company is a reputable and reliable provider of cutting tools and equipment, with a strong commitment to delivering excellence and customer satisfaction. With its comprehensive product line, custom solutions, emphasis on customer service, dedication to innovation, and strict quality control measures, Cutting Tools And Equipment Company is well-positioned to meet the evolving needs of its clients and continue to thrive in the cutting tools industry.

High-Quality Hollow Mill Cutter for Precision Machining

[Hollow Mill Cutter] Introduces Innovative Cutting Solution for Precision Machining Applications[Hollow Mill Cutter] is a leading manufacturer and supplier of cutting tools for precision machining applications. With a strong commitment to innovation and continuous improvement, [Hollow Mill Cutter] has recently introduced an innovative cutting solution that is set to revolutionize the industry.The new cutting solution, which has been developed using advanced materials and cutting-edge technologies, offers superior performance and efficiency for a wide range of machining tasks. Whether it's milling, turning, or drilling, the [Hollow Mill Cutter] is designed to deliver exceptional results, making it the go-to choice for machining professionals across the globe.Featuring a hollow design, the [Hollow Mill Cutter] offers several key advantages over traditional solid cutting tools. The hollow construction allows for better chip evacuation, reducing the risk of chip buildup and associated performance issues. This results in cleaner cuts, improved surface finish, and extended tool life, ultimately leading to higher productivity and cost savings for users.The [Hollow Mill Cutter] is also designed to provide maximum rigidity and stability during machining operations, ensuring precise and accurate cuts every time. This is made possible by the use of high-quality materials and advanced manufacturing techniques, which have been carefully optimized to deliver the best possible performance.In addition, the [Hollow Mill Cutter] is available in a wide range of sizes and configurations, making it suitable for various machining applications across different industries. Whether it's aerospace, automotive, medical, or general manufacturing, the [Hollow Mill Cutter] is capable of meeting the diverse needs of modern machining professionals.As a company, [Hollow Mill Cutter] is committed to providing its customers with cutting-edge solutions that deliver exceptional value and performance. With a team of experienced engineers and technical specialists, [Hollow Mill Cutter] is constantly pushing the boundaries of innovation to bring new and improved products to the market.Furthermore, [Hollow Mill Cutter] places a strong emphasis on quality and reliability, ensuring that its cutting tools meet the highest industry standards and customer expectations. By maintaining a strict quality control process and investing in state-of-the-art manufacturing facilities, [Hollow Mill Cutter] is able to produce cutting tools that are second to none in terms of performance and durability.In line with its commitment to customer satisfaction, [Hollow Mill Cutter] also provides comprehensive technical support and after-sales service to its clients. This includes expert advice on tool selection, machining process optimization, and troubleshooting, ensuring that customers are able to maximize the potential of their cutting tools and achieve the best possible results.With the introduction of the innovative [Hollow Mill Cutter], [Hollow Mill Cutter] has once again demonstrated its leadership in the cutting tool industry. By combining advanced technology, precision engineering, and a dedication to customer satisfaction, [Hollow Mill Cutter] is set to continue driving innovation and setting new standards for cutting tool performance in the years to come.For more information about the [Hollow Mill Cutter] and its cutting-edge solutions for precision machining applications, please visit [company website] or contact [company contact information].

Ultimate Guide to Engine Cylinder Boring Tools: Everything You Need to Know

Introducing a Revolutionary Engine Cylinder Boring ToolIn today's fast-paced world, efficiency and innovation are key factors in the success of any business. This rings especially true in the automotive industry, where constant advancements in technology and tools are essential to stay ahead of the competition. With this in mind, we are pleased to introduce our latest innovation - the Engine Cylinder Boring Tool.Designed and manufactured by our company, the Engine Cylinder Boring Tool is a game-changer in the field of engine maintenance and repair. This state-of-the-art tool is engineered to improve the precision and efficiency of boring engine cylinders, offering a reliable and cost-effective solution for automotive professionals.The Engine Cylinder Boring Tool boasts a range of features that set it apart from the competition. Its cutting-edge design allows for fast and accurate boring of engine cylinders, ensuring a precise and uniform finish every time. The tool is also equipped with advanced technology that minimizes vibration and reduces noise levels, providing a more comfortable and user-friendly experience for technicians.One of the key advantages of our Engine Cylinder Boring Tool is its versatility. It is compatible with a wide range of engine types and sizes, making it an indispensable tool for automotive workshops and service centers. Whether working on a small compact car or a heavy-duty truck, our tool delivers consistent and reliable results, meeting the diverse needs of our customers.In addition to its exceptional performance, the Engine Cylinder Boring Tool is also built to last. Constructed from high-quality materials and manufactured to the highest standards, this tool is designed for durability and longevity, making it a sound investment for any automotive business.Furthermore, our company takes pride in providing exceptional customer support and service. We understand the importance of quick and efficient solutions, which is why we offer comprehensive technical assistance and training for our customers. Our team of experts is dedicated to ensuring that our clients get the most out of our products, enabling them to maximize their productivity and profitability.With the growing demand for reliable and efficient engine maintenance tools, the Engine Cylinder Boring Tool has already garnered significant interest from automotive professionals worldwide. Its cutting-edge features and superior performance make it a desirable choice for businesses looking to enhance their operations and deliver exceptional results to their customers.The Engine Cylinder Boring Tool is just one example of our commitment to innovation and excellence in the automotive industry. With a strong focus on research and development, we continue to explore new technologies and solutions to meet the evolving needs of our customers. Our goal is to empower automotive professionals with the tools they need to succeed, and the Engine Cylinder Boring Tool is a testament to that dedication.In conclusion, the Engine Cylinder Boring Tool is a revolutionary advancement in engine maintenance and repair, offering unparalleled performance, versatility, and durability. Backed by our company's commitment to excellence and customer support, this tool is set to make a significant impact in the automotive industry. We are proud to introduce this game-changing innovation and look forward to seeing the positive impact it will have on businesses and professionals around the world.

High-Quality 6mm End Mill for Precision Machining

As the demand for precision engineering and manufacturing continues to soar, companies across various industries are constantly looking for high-quality tools and equipment to meet their production needs. Recognizing this demand, [Company Name] has recently introduced their latest innovation - the 6mm End Mill, designed to meet the needs of modern machining processes.[Company Name] has been a leading provider of cutting tools and solutions for the manufacturing industry for over two decades. With a commitment to delivering high-quality products and exceptional customer service, the company has established a strong presence in the market and earned a reputation for excellence.The 6mm End Mill is the latest addition to [Company Name]'s extensive range of cutting tools, designed to offer superior performance and reliability for a wide range of machining applications. Made from high-quality materials and precision-engineered to the highest standards, the end mill is capable of delivering exceptional results in various machining operations, including milling, contouring, and other cutting processes.One of the key features of the 6mm End Mill is its advanced cutting geometry, which allows for smooth and efficient chip removal, resulting in improved surface finish and extended tool life. This innovative design ensures that the end mill can maintain consistent performance across a range of materials, including steel, aluminum, and other alloys, making it a versatile solution for manufacturers working with diverse materials.In addition to its cutting-edge design, the 6mm End Mill also incorporates [Brand Name]'s proprietary coating technology, which enhances the tool's wear resistance and thermal stability. This ensures that the end mill can withstand the high temperatures and heavy usage associated with modern machining processes, prolonging its lifespan and reducing the need for frequent tool changes.Furthermore, the 6mm End Mill is engineered to deliver high precision and accuracy, allowing manufacturers to achieve tight tolerances and fine surface finishes with ease. This level of precision is crucial for industries such as aerospace, automotive, and medical manufacturing, where the quality of the end product is of utmost importance.Speaking about the launch of the 6mm End Mill, [Spokesperson Name], the [Job Title] at [Company Name], expressed their excitement about the new product, stating, "We are thrilled to introduce the 6mm End Mill to the market. As a company dedicated to innovation and continuous improvement, we believe that this new addition to our product lineup will empower manufacturers to take their machining capabilities to the next level, ultimately supporting their growth and success."[Company Name] is also offering comprehensive technical support and guidance to help customers optimize the performance of the 6mm End Mill in their specific applications. With a team of experienced engineers and cutting tool specialists, the company is committed to providing tailored solutions that meet the unique needs and challenges of their customers.In conclusion, the introduction of the 6mm End Mill is a testament to [Company Name]'s commitment to advancing the field of cutting tools and supporting the evolving needs of modern manufacturers. With its high performance, precision engineering, and versatile capabilities, the end mill is set to make a significant impact in the industry, empowering businesses to enhance their productivity and quality standards.

Top 10 Steel Cutting Discs for Precision Cutting in 2022

Steel Cutting Disc is a crucial tool in the metalworking industry, and it has been a game-changer for many businesses. There are a variety of cutting discs on the market, and one brand in particular has proven to be a leader in the industry.The company, [Company Name], has been at the forefront of producing high-quality steel cutting discs for over a decade. They have established themselves as a reliable and trusted supplier of cutting discs, catering to a wide range of industries including metal fabrication, construction, and automotive, among others. Their commitment to producing top-notch products has earned them a strong reputation in the market.The steel cutting discs manufactured by [Company Name] are known for their durability and efficiency. They are designed to cut through a wide range of materials including steel, stainless steel, and aluminum, with precision and speed. This has made them a go-to choice for many businesses looking to streamline their cutting processes.In addition to their exceptional performance, [Company Name]’s cutting discs are also designed with safety in mind. They undergo rigorous testing to ensure that they meet industry standards and provide a safe working environment for operators. This dedication to safety has not gone unnoticed, as many businesses have chosen [Company Name] as their preferred supplier for cutting discs.One of the key factors that sets [Company Name] apart from its competitors is their continuous innovation in product development. They invest heavily in research and development to improve their cutting disc technology, resulting in innovative products that offer enhanced performance and longevity. This commitment to innovation has allowed [Company Name] to stay ahead of the curve and meet the evolving needs of their customers.Furthermore, [Company Name] has also placed a strong emphasis on customer service and support. They have a dedicated team of experts who provide guidance and assistance to their customers, ensuring that they get the right cutting disc for their specific application. This personalized approach has helped [Company Name] build strong and lasting relationships with their clients.Recently, [Company Name] introduced a new and improved steel cutting disc that has been generating buzz in the industry. This cutting disc boasts enhanced cutting performance and longer lifespan, making it an attractive option for businesses looking to improve their cutting operations. With the introduction of this new product, [Company Name] has once again demonstrated their commitment to delivering cutting-edge solutions to their customers.In conclusion, [Company Name] has solidified its position as a leading supplier of steel cutting discs in the market. Their dedication to producing high-quality, safe, and innovative products, paired with their exceptional customer service, has earned them the trust and loyalty of many businesses. As they continue to push the boundaries of cutting disc technology, it is clear that [Company Name] will remain a strong force in the industry for years to come.

High-Quality End Mill Bits for Your Machining Needs

End Mill Bits, a leader in the manufacturing of high-quality cutting tools, has recently announced the release of their latest line of end mill bits. These new end mill bits are designed to provide superior performance and precision in machining operations, making them an ideal choice for a wide range of industries and applications.The end mill bits manufactured by End Mill Bits are known for their durability, reliability, and exceptional performance. The company has a strong reputation for producing cutting-edge tools that meet the high demands of modern machining processes. Their commitment to quality and innovation has made them a trusted name in the industry.The new line of end mill bits features a variety of advanced features and cutting-edge technology that sets them apart from the competition. They are engineered to deliver exceptional precision and superior performance, making them an essential tool for professionals and enthusiasts alike. Whether for use in aerospace, automotive, medical, or general machining applications, these end mill bits are designed to exceed expectations.One of the key features of the new end mill bits is their advanced coating technology. This coating provides enhanced wear resistance, reduced friction, and improved chip evacuation, allowing for smoother and more efficient cutting operations. The result is improved tool life, reduced downtime, and increased productivity.In addition, the end mill bits are designed with optimized flute geometries and cutting-edge designs that allow for high-performance machining in a variety of materials, including steel, aluminum, titanium, and exotic alloys. The precise and reliable performance of these end mill bits makes them an ideal choice for a wide range of machining applications, from roughing to finishing operations.End Mill Bits continues to set the standard for cutting tool technology through their dedication to research, development, and innovation. The company invests heavily in state-of-the-art manufacturing processes and quality control measures to ensure that their products meet the highest standards of excellence. Their team of experienced engineers and technicians work tirelessly to push the boundaries of what is possible in cutting tool technology.With a strong focus on customer satisfaction, End Mill Bits is committed to providing exceptional support and service to their customers. The company works closely with clients to understand their specific needs and challenges, and they offer personalized solutions to help them achieve their machining goals. End Mill Bits is more than just a supplier; they are a trusted partner in the success of their customers' operations.End Mill Bits understands the importance of staying ahead of the curve in a rapidly evolving industry. As a result, they are constantly researching and developing new technologies and materials to improve the performance of their cutting tools. The release of their latest line of end mill bits is a testament to their ongoing commitment to innovation and excellence.In conclusion, the new line of end mill bits from End Mill Bits represents a significant leap forward in cutting tool technology. With their advanced features, cutting-edge designs, and superior performance, these end mill bits are setting a new standard for precision and reliability in machining operations. As End Mill Bits continues to push the boundaries of what is possible in cutting tool technology, they remain an industry leader that is dedicated to providing exceptional products and support to their customers.

High-Quality Cnc Milling Bits for Precision Manufacturing

Cnc Milling Bits, an essential tool for precision machining, have been revolutionizing the manufacturing industry with their unmatched efficiency and accuracy. These cutting-edge tools have been the cornerstone of machining processes, enabling companies to produce intricate and complex parts with ease. With the rise of advanced manufacturing techniques, the demand for high-quality Cnc milling bits has surged, prompting manufacturers to innovate and develop cutting-edge solutions to meet the growing needs of the industry.One such company at the forefront of the Cnc milling bit industry is {}. With a strong focus on research and development, the company has been pioneering the design and production of Cnc milling bits that set new standards for precision and performance. Their commitment to innovation and quality has positioned them as a trusted partner for machining centers and manufacturing facilities around the world.The company's proprietary manufacturing process and state-of-the-art facilities allow them to produce Cnc milling bits that are not only durable and long-lasting but also deliver exceptional cutting performance. By utilizing the latest technology and materials, they have been able to engineer Cnc milling bits that can withstand the rigors of high-speed machining and deliver unparalleled accuracy and surface finish.The versatility of their Cnc milling bits makes them suitable for a wide range of applications, including aerospace, automotive, medical, and general manufacturing. From aluminum and titanium to hardened steels and exotics materials, their Cnc milling bits are designed to tackle the toughest materials with ease, making them an ideal choice for demanding machining operations.In addition to their standard offerings, the company also provides custom Cnc milling bits tailored to the specific needs of their customers. By collaborating closely with their clients, they are able to develop bespoke cutting solutions that optimize performance and productivity, ultimately driving operational efficiency and cost savings.Beyond their cutting-edge products, the company's commitment to customer satisfaction sets them apart in the industry. With a dedicated team of technical experts and engineers, they offer comprehensive support and guidance to help their customers select the right Cnc milling bits for their applications. From tool selection and optimization to troubleshooting and maintenance, they are dedicated to ensuring their customers achieve the best possible results.As the manufacturing industry continues to evolve, the demand for high-performance Cnc milling bits will only continue to grow. With their unwavering commitment to innovation and quality, {} is well-positioned to meet the evolving needs of the industry and support the advancement of modern manufacturing practices.In conclusion, Cnc milling bits are indispensable tools for precision machining, and companies like {} are driving the industry forward with their cutting-edge solutions. With a focus on innovation, quality, and customer satisfaction, they are a trusted partner for manufacturers seeking to achieve a competitive edge through superior machining performance.

High-Quality Carbide Tipped Lathe Tools for Precision Machining

Carbide Tipped Lathe Tools have long been a staple in the machining industry, providing precision and durability for a wide range of applications. As a leading manufacturer in the industry, {Company Name} has established itself as a go-to source for high-quality carbide tipped lathe tools that meet the demanding needs of modern machining.With a commitment to innovation and excellence, {Company Name} has continued to push the boundaries of what is possible in the realm of carbide tipped lathe tools. Their dedication to research and development has led to the creation of cutting-edge tools that deliver unrivaled performance and reliability.One of the key advantages of carbide tipped lathe tools is their ability to withstand the high temperatures and extreme forces that are common in machining operations. This is essential for maintaining precision and achieving the desired result in a wide range of applications.{Company Name} has recognized the importance of this and has invested heavily in the development of carbide tipped lathe tools that excel in these demanding conditions. Their tools are designed to provide consistent performance, even in the most challenging environments, ensuring that machinists can rely on them to deliver exceptional results day in and day out.In addition to their high-performance capabilities, {Company Name}'s carbide tipped lathe tools are also known for their exceptional durability. This is a critical factor in the machining industry, where tools are subjected to significant wear and tear. {Company Name} understands the importance of longevity and has engineered their tools to withstand the rigors of daily use, providing machinists with a reliable and cost-effective solution for their machining needs.Furthermore, {Company Name} takes great pride in the precision and accuracy of their carbide tipped lathe tools. Every tool is manufactured to the highest standards, ensuring that they meet the exacting requirements of modern machining. This level of precision is essential for producing high-quality components and achieving the desired results in various industrial applications.{Company Name}'s commitment to quality extends beyond their products to encompass their customer service and support as well. They understand that their success is dependent on the success of their customers, and they go above and beyond to provide the guidance and assistance needed to maximize the performance of their carbide tipped lathe tools.Through their dedication to excellence, {Company Name} has established itself as a trusted and respected provider of carbide tipped lathe tools in the machining industry. Their tools are relied upon by machinists around the world to deliver exceptional results, and their reputation for quality and innovation continues to set them apart from the competition.In conclusion, {Company Name} is a leading manufacturer of carbide tipped lathe tools, offering a comprehensive range of high-performance, durable, and precise tools that meet the demanding needs of modern machining. Their commitment to excellence, innovation, and customer satisfaction has solidified their position as a go-to source for high-quality carbide tipped lathe tools in the industry. As they continue to innovate and push the boundaries of what is possible in machining, {Company Name} is poised to remain at the forefront of the industry for years to come.